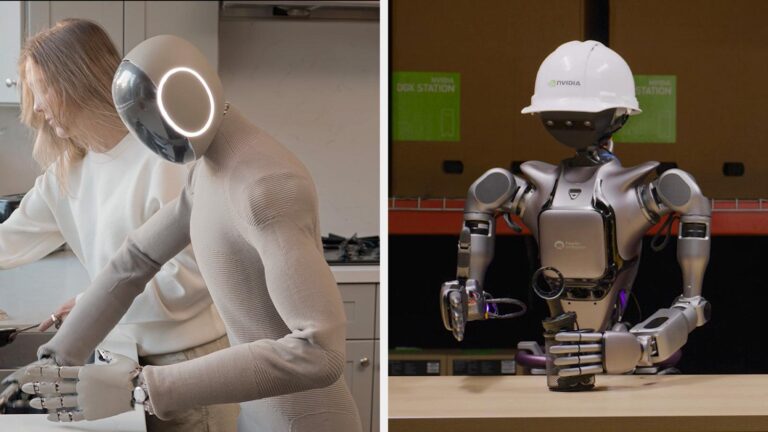

Nvidia and Foxconn Advance Humanoid Robotics Integration at Houston AI Server Facility

Nvidia and Foxconn are reportedly progressing toward a pioneering collaboration to deploy humanoid robots within a state-of-the-art AI server manufacturing plant located in Houston. This initiative is designed to embed sophisticated robotics into the production workflow, aiming to boost operational productivity and foster innovation. By combining Foxconn’s manufacturing prowess with Nvidia’s cutting-edge AI capabilities, the partnership exemplifies the accelerating trend of automation in semiconductor and server fabrication sectors.

Highlights of the proposed robotic implementation include:

- Humanoid robots engineered for intricate assembly and routine maintenance

- Seamless integration with Nvidia’s AI-powered server management platforms enabling dynamic process adjustments

- Enhanced safety protocols facilitating cooperative human-robot interactions

- Predictive maintenance systems leveraging AI analytics to minimize downtime

| Technology | Advantage | Outcome |

|---|---|---|

| Humanoid Robotics | Accurate and consistent assembly | Improved product uniformity |

| AI System Integration | Intelligent process control | Enhanced operational throughput |

| Collaborative Safety Design | Reduced workplace hazards | Lower accident rates |

Transforming Manufacturing Efficiency and Workforce Dynamics with Humanoid Robots

The introduction of humanoid robots at the Houston AI server plant is set to revolutionize manufacturing workflows by elevating efficiency and precision. These robots, designed to replicate human dexterity and cognitive functions, will handle repetitive and delicate tasks with greater speed and accuracy, thereby shortening production cycles and minimizing errors. Expected efficiency improvements include:

- Continuous 24/7 operation without fatigue-related slowdowns

- Superior precision in assembly and inspection processes

- Real-time adaptive troubleshooting to reduce unplanned downtime

Nonetheless, this technological shift will reshape workforce dynamics. While some manual roles may diminish, new opportunities will arise in robot oversight, maintenance, and AI system management. Nvidia and Foxconn are anticipated to invest heavily in retraining initiatives to equip employees with skills necessary for these emerging roles. Workforce implications encompass:

| Factor | Impact |

|---|---|

| Job Displacement | Decline in demand for manual assembly labor |

| Skill Evolution | Growth in demand for robotics technicians and AI engineers |

| Workplace Environment | Increased focus on human-robot collaboration spaces |

Navigating Challenges and Leveraging Opportunities in Robotics Integration for AI Server Manufacturing

Incorporating advanced humanoid robots into the AI server production line in Houston presents several technical and operational challenges. Achieving the required micrometer-level precision in assembling sensitive AI components demands robots equipped with sophisticated sensory and feedback mechanisms. Additionally, these robots must integrate flawlessly with existing automated systems to avoid workflow disruptions. Cybersecurity is another critical concern, as safeguarding sensitive manufacturing data during robot-server communications is paramount.

On the flip side, this integration offers transformative benefits. Robots capable of continuous operation and real-time learning can drastically reduce production cycle times and human error rates. The synergy between human workers and robots can also enhance workplace safety and allow human staff to concentrate on higher-value activities such as innovation and quality assurance. Anticipated advantages include:

- Greater operational flexibility through AI-driven process refinement

- Cost savings by automating repetitive tasks and minimizing downtime

- Improved quality assurance via AI-powered anomaly detection and advanced sensors

| Challenge | Opportunity |

|---|---|

| Precision assembly of fragile AI components | Enhanced manufacturing accuracy and consistency |

| Integration with legacy automation systems | Smoother workflows and reduced bottlenecks |

| Ensuring cybersecurity in robot-server communication | Protected data exchange with AI-enhanced threat detection |

Strategies to Optimize Robotics Adoption in Technology Manufacturing

Maximizing the benefits of humanoid robot deployment requires a holistic approach that fosters collaboration between human operators and robotic systems. Beyond investing in advanced robotics, companies must prioritize workforce development through comprehensive training programs that cover robot operation, monitoring, and troubleshooting. Such initiatives will enhance productivity and reduce downtime, enabling manufacturers to remain competitive in a fast-evolving technological landscape.

Moreover, adopting modular and scalable robotic platforms tailored to specific production needs will provide the flexibility to adapt quickly to new product lines or process modifications. Leveraging AI-driven data analytics from robotic operations can further optimize production schedules and enable predictive maintenance, ensuring continuous peak performance without costly interruptions.

- Implement interdisciplinary training to strengthen human-robot collaboration

- Deploy modular robotic systems for easy upgrades and adaptability

- Utilize AI analytics for predictive maintenance and process enhancement

- Adopt phased integration to minimize operational risks during transition

| Strategy | Benefit | Implementation Method |

|---|---|---|

| Collaborative Training | Fewer errors and improved efficiency | Ongoing workshops and immersive VR simulations |

| Modular Robotics | Cost-effective scalability | Standardized components and plug-and-play modules |

| AI-Powered Analytics | Proactive maintenance and optimized workflows | Real-time monitoring platforms |

| Phased Rollout | Reduced disruption during adoption | Incremental robot deployment stages |

Conclusion

As Nvidia and Foxconn move closer to deploying humanoid robots in Houston’s AI server manufacturing facility, this collaboration represents a pivotal advancement in automating complex industrial processes. If successfully implemented, it could establish a new benchmark for robotics-driven efficiency and precision in high-tech manufacturing. Industry observers will be keenly watching this partnership, which has the potential to redefine the future of AI-enhanced production environments.